FOOD INDUSTRY AND CRAFT MELA

PUNJAB AGRICULTURAL UNIVERSITY, LUDHIANA

October 11, 2022

The Food Industry and Craft Mela was organised at PAU Ludhiana on October 11, 2022. It involved major departments of the university related to food processing, nutrition, apparels, bee keeping and mushroom production etc. and Skill Development Centre. This Mela is of recent origin, started in the year 2014 and is primarily targeted at developing cooperation between industry, academia, research, raw material producers and the consumers. The focus of the event is on accelerating the interactions between food industry, academia, research institutes, self-help groups, farmer producer organizations, young entrepreneurs and Start-ups working in the field of agro-processing. This Mela intends to provide the platform to the budding entrepreneurs especially from the rural areas to show case their processed products, get exposure to state-of-the-art technologies in the fields of food processing. PAU is playing the role for direct interaction among the producer, processor and buyer/consumer. A large number of self help groups, small entrepreneurs and other stake holders participated in the exhibition for display and sale of their products. A strong foot fall of nearly 25000-30000 persons from Ludhiana and nearby areas visited the exhibition.

GLIMPSES OF FOOD INDUSTRY AND CRAFT MELA

1st Sarkar-Kisan Milni (February 12, 2023)

Food Processing, Value Addition and Start Ups

List of training courses on agro processing regularly organized by the department

|

S. No

|

Name of training course

|

Duration and frequency

|

Beneficiaries

|

|

1

|

Agro processing and machinery

|

5 days (3-4 times a year)

|

Farmers, state level govt. functionaries

|

|

2

|

Agro processing industries at small scale level

|

5 days (3-4 times a year)

|

Farmers

|

|

3

|

Storage and processing of horticultural produce

|

3 days (2 times a year)

|

Horticultural development officers

|

|

4

|

Need based training courses

- Processing of honey

- Processing of jaggery

- Processing of turmeric and other spices

|

2 days duration, as and when required

|

Farmers

|

|

5

|

Entrepreneurship Development in Food processing for Livelihood”

|

1-2 days (4-5 times a year)

|

SC/ST candidates

|

PRIMARY PROCESSING OF FOOD GRAINS THROUGH AGRO PROCESSING CENTRE FOR BETTER LIVELIHOOD

Rural entrepreneurship through suitable agro-processing models/centre is essential to increase the income of the farmers, provide significant employment opportunities to the rural youth and reduce huge amount of post harvest losses especially in cereals, spices, cotton and oil-seeds. The Department of Processing and Food Engineering, PAU Ludhiana has been the role model in the country in realization of the concept of establishing agro processing complexes for value addition in post harvest losses, income and employment generation in rural areas, thereby causing reduction in urban pull for rural youths and achieving diversification concepts in agriculture. Hence we need to focus on increasing the returns to the farming community as well as reducing the post-harvest losses and wastages.

An agro-processing centre is an enterprise where the required facilities for primary and secondary processing, storage, handling and drying of cereals, pulses, oilseeds and spices are made available on either for self-processing or on custom hire basis to rural people. Value-added agro-based products and processed food items are also prepared and marketed by these centers. This type of center could be managed by individuals/ SHG/FPO/organizations/voluntary organization at village level. Based on the available produce at farm-gate, knowledge of farmers in handling and processing (traditional) of agricultural produce for their own consumption & their impression about the quality expectation of processed products, there is strong case for taking up agricultural production to next level through secondary agriculture initiatives with the involvement of progressive farmers.

The concept of APCs was to process the grains (durable crops) at the village level to substantially enhance the income of the farmers. Moreover, the primary processed products from wheat, paddy, oilseeds, pulses etc are of daily use in every household. So there lies a great potential for the primary processing of these durable food grains. These agro processing complexes have been found to be technically feasible, economically viable and socially acceptable models. These complexes consist of two or more machines for processing at farm/village level. The machines are mini rice mill, baby oil expeller, small atta chakkies and large atta chakkies with scouring machine, masala grinder, pulse cleaner cum grader and feed mill along with construction and installation costing approximate Rs. 25-30 lakhs. A desired covered space of approx. 1800-2700 square feet is required for the installation of all these machines.

Small farmers/ entrepreneurs can setup APC as a single unit or they can install just one component of APC such as Atta Chakki alone, mini rice sheller, oil expelling unit, feed mill unit or turmeric processing unit (Spice grinding unit). The technologies for such processing may not be very complicated and produce from such APC is wholesome having better nutrition for common population rather than high level of refinement that cater to high end industry. The following advantages have been experienced through APC’s in rural areas:

- Employment generation in the production catchments

- Migration check of unemployed rural youth to urban areas

- Processing of farm product locally

- Increased farm income

- Reduced transportation costs of raw materials/products

- Adulteration free product

- Ease of disposal of waste

- Minimizes pollution from agro-processing in cities

A number of such complexes have been adopted by the farmer/entrepreneurs at various places in Punjab. These are technically feasible and economically viable units. Details of agro processing machinery along with their cost are given in table 1:

Table 1 Agro Processing Centre Machinery

|

Crop/ Commodity

|

Processed Products/ By-products

|

Components/ machines

|

Capacity

|

Cost (Rs.)

|

|

Paddy

|

Rice/Husk and bran

|

Mini rice mill with two polishers & elevators

|

250 kg/hr

|

3,70,000

|

|

Oilseeds

|

Filtered oil/Oil Cake

|

Baby oil expeller with filter press

|

100 kg/hr of oilseed

|

3,50,000

|

|

Wheat

|

Wheat Flour/Bran

|

Atta Chakki (with Scourer)

|

700 kg/hr

|

7,00,000

|

|

Wheat

|

Wheat Flour/Bran

|

Atta Chakki(Rajasthani)

|

150 kg/hr

|

50,000

|

|

Turmeric, Chilli

|

Turmeric and Chilli powder

|

Masala Grinder

|

50 kg/hr

|

70,000

|

|

Pulses

|

Graded pulses

|

Pulse cleaner-cum-grader

|

100 kg/hr

|

1,00,000

|

|

Mixture of by-products

|

Cattle feed

|

Cattle feed mill

|

3 qtls/hr

|

3,50,000

|

|

|

|

Packaging machinery

|

|

3,00,000

|

|

Electric motor with fitting

|

20-25 hp

|

1,50,000

|

|

Total cost on machinery

|

|

24,00,000

|

* The cost of the machine can increase/decrease as per the manufacturer/dealer

a. Extra Cost of Rs 8, 00,000 (for construction of APC shed along with installation of machinery)

Small scale level improved machinery for processing of these crops is available in the main industrial cities of Punjab i.e Ludhiana, Batala, Rajpura, Khanna etc.

After deciding the technologies, the components of agro industrial complex can be finalized.

Steps involved in establishing Agro Processing Centre

A wide variety of equipments are required based on the crop and operations for developing the processed product. For selecting a suitable agro industrial technology/equipment in rural areas, the following important points should be given due consideration:

- Availability of raw material

- Technology/process to be used for processing

- Volume of production

- Facility for storage and marketing

Apart from proper selection of equipment, the assessment related to availability of raw material and market potential is also of prime importance. The collection of benchmark information of selected village and cluster of villages on crops grown, processing of farm produce, and the demand for processed products is the first crucial step to proceed further. It is followed by identifying corresponding post-harvest equipments/technologies based on crops production scenario of cluster and studying their techno-economic feasibility. A license from appropriate authorities of the government to take up processing activities is required to install processing equipments. The strategies to enable the APC to run for more than nine months in a year should be made in addition to developing modalities for credit assistance from banks to procure additional processing equipment as and when needed. Involvement of Self-Help Groups of Women in the value-added activities would be beneficial for marketing of processed products.

A number of steps need to be followed in sequence for the establishment of APC. The steps involved are identification /selection of Agricultural produce; preparation of feasibility report; site selection for establishing APC; registration with the Small Scale Industries(SSI); Applying for power supply connection; monetary assistance, if required through bank loan; installation of machines; applying for subsidy, Agmark registration for products and marketing and sales.

APCs can generate a platform to process the raw produce with ensured good quality finished product and are technically feasible and economically viable units. Presently more than 300 of such APCs have been installed by the farmers/rural youth under the guidance of PAU directly/indirectly and are being running successfully in different parts of state. Presently 25-40% subsidy on machinery is provided by KVIC/MoFPI. The entrepreneurs who had already installed the APC with our guidance, running it successfully and are fetching good financial capital with monthly profit of approx. Rs 0.50 to 1.00 lakhs apart from providing employment to 2-5 persons. The state has a lot of potential for installing similar units all over Punjab.

The department has been organizing training courses regularly on agro based industries to provide the technical knowledge for setting up of APCs to its stake holders i.e. farmers/ small entrepreneurs etc.

IMPORTANT TIPS IN THE MANUFACTURE & STORAGE OF GUR

Jaggery is a wholesome food. It contains 0.6%-1.0% minerals, important among them are iron (11mg%), calcium (0.4%), magnesium and phosphorous (0.045%). Jaggery also contains reducing sugars including glucose and fructose (10-15%), protein (0.25%),and fat (0.05%). Daily use of jaggery may increase human life span.Jaggery has been considered as organic and nutritional sweetener with high energy level full of health promoting minerals.. The consumption of Jaggery in daily diet can help prevent the atmospheric pollution related adverse effect and the incidence of lung cancer among the vulnerable work force operating in hazardous environment. In addition to the various losses associated to the manufacturing process for making gur, it also presents problems for its safe storage. More than 3 million tones of gur is kept safely every year for consumption during and after rainy season.

Following are the main steps involved in the production of gur & related products which needs careful considerations:

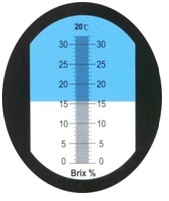

EXTRACTION OF JUICE: The extraction of cane juice is influenced by the sugarcane variety, maturity, environment conditions, its handling and type of cane crusher employed. Fully matured cane having TSS more than 19% and fiber content near to 12% yields good quality jaggery with higher recovery

CLARIFICATION: The purpose of clarification is to make the extracted juice clear as well as light in colour and to prevent sucrose inversion. It can be minimized by liming juice to adjust pH near to neutral. The application of vegetable based clarificant (wild okra/Deola) is quite popular

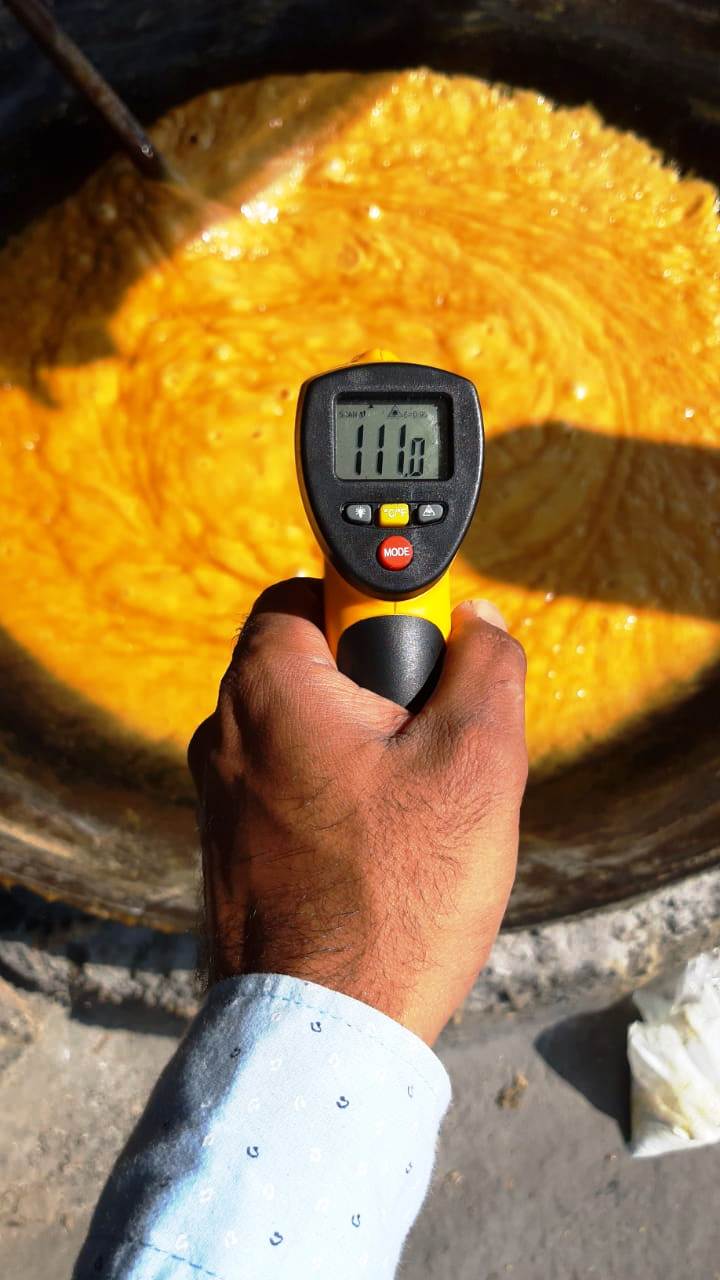

CONCENTRATION OF JUICE; The clear juice is boiled vigorously in the open pans to evaporate water thus concentrating it into thick slurry which could solidify, on cooling, into gur.

|

|

For processing Solid Jaggery, Temp. = 114 0C

Powder Jaggery Temp. = 121 0C

Granular Jaggery, Temp. =124 0C

|

FINISHING & MOULDING: After little bit cooling, the concentrated material is pounded vigorously by wooden club called ‘Chandra’. ‘Bhallis’ of gur are made by hand when concentrated mass has cooled down sufficiently orthe slurry is poured into molding frame.

STORAGE OF JAGGERY: safe storage of jaggery is very important for this agro based commercial activity. It has been estimated that a substantial amount of jaggery produced ( one third to one half of the jaggery needed to be stored. The estimates showed that 5-10% of stored jaggery is lost because of its hygroscopic nature. Darkening of jaggery colour during storage under ambient condition is another major problem

Jaggery has been considered as a traditional healthier sweetener produced out of sugarcane juice due to its health benefits. However, Jaggery is highly sensitive product, that require attention right from cultivation of sugarcane to processing and storage |